Manufacturer 4A vs 3A Molecular Sieves in LNG Dehydration

LNG dehydration mainly uses 4A molecular sieves for water and hydrocarbon removal, while 3A suits cases needing zero hydrocarbon adsorption.

Selective Adsorption:

With a pore size of ~3Å, 3A molecular sieves adsorbs water molecules (~2.6Å) while excluding ethanol (~4.4Å), enabling efficient dehydration.

Dynamic Process:

In fixed-bed towers, wet ethanol passes through the molecular sieve, where water is adsorbed and dry ethanol exits. Heating at 200–300°C enables regeneration of the sieve.

Method Advantages Disadvantages

3A Molecular Sieve High purity, low ethanol loss Requires regular regeneration

Azeotropic Distillation Continuous operation Uses toxic solvents (e.g., benzene)

Pervaporation Membrane Energy efficient Membranes clog easily, low throughput

3A molecular sieve offers an efficient, environmentally friendly solution for ethanol dehydration. Its high performance and purity make it ideal for fuel, pharmaceutical, food, and lab-grade applications. Optimal system design should be based on processing scale, cost, and energy requirements.

LNG dehydration mainly uses 4A molecular sieves for water and hydrocarbon removal, while 3A suits cases needing zero hydrocarbon adsorption.

Achieve ultra-deep dehydration of cracked gas with 3A molecular sieves—remove water without ethylene/propylene loss, ensuring catalyst life and product purity.

Home Desiccant Activated Alumina for air compressor drying gas purification wholesale Email WhatsApp Product Inroduction: Desiccant Activated Alumina for air

Home Adsorbent Zeolite 13x Molecular Sieve for Removing Odor From LPG in air Freshener Plant Email WhatsApp Product Inroduction: Adsorbent Zeolite

As a leading molecular sieve manufacturer, we share the latest industry news and insights on adsorbents like molecular sieves, sieve powder, and activated alumina.

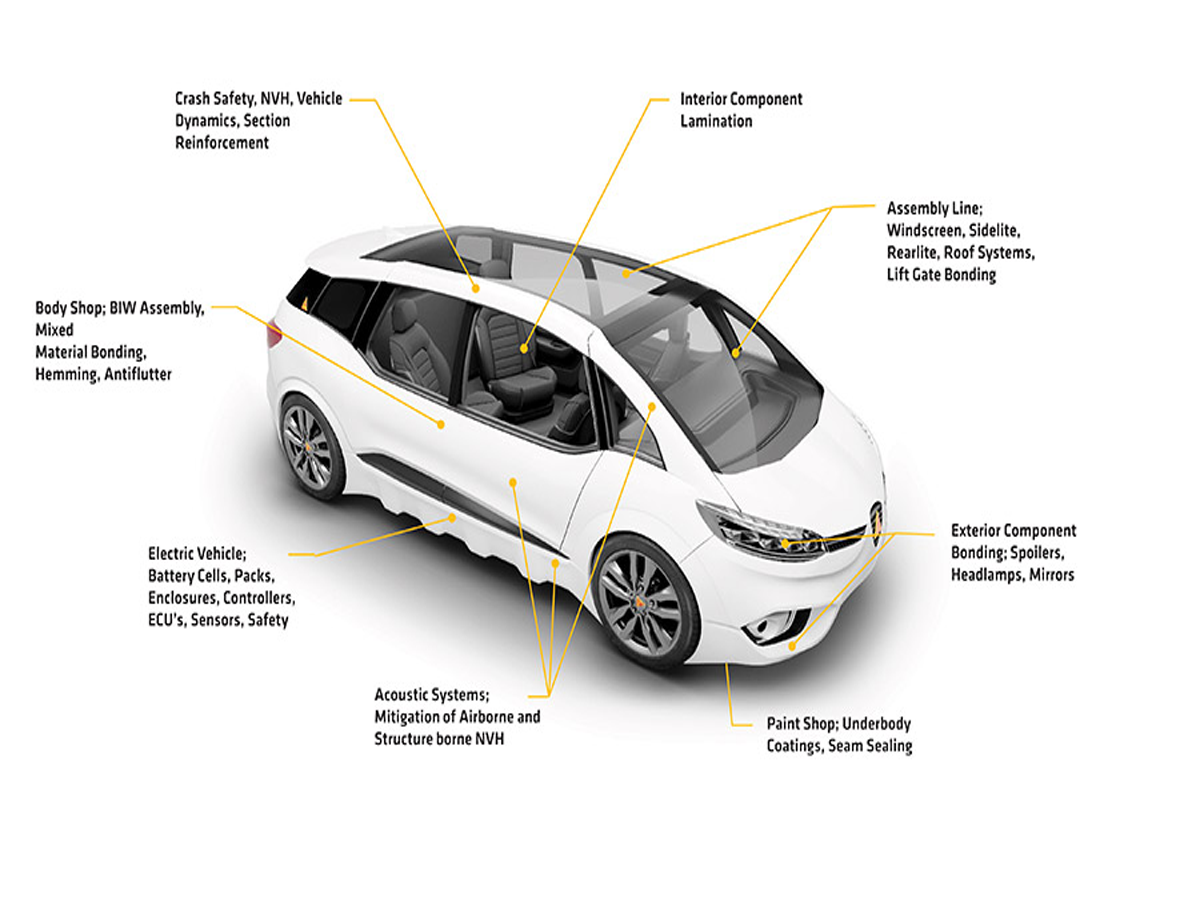

3A molecular sieve powder adsorbing moisture is ideal for 2K PU and moisture-curing 1K PU adhesives

3 proven regeneration techniques to extend molecular sieve desiccants lifespan, reduce costs, and ensure stable performance in air separation and gas processing.

Achieve ultra-deep dehydration of cracked gas with 3A molecular sieves—remove water without ethylene/propylene loss, ensuring catalyst life and product purity.